Want to Learn More?

Size Matters

If you’ve ever taken on a building project, you know that size matters. You don’t want to pay for more than you need, so when it comes to fresh concrete, the size of your project and the size of the equipment are important considerations. This is where our volumetric concrete mixer trucks come in handy. Unlike conventional ready-mix trucks, they can deliver the exact amount of concrete you need, on-site, when you need it, so you only pay for what you use.

Let’s walk you through the different sizes of projects, so you understand how it all works and the benefits of on-demand concrete mixing and pouring.

SMALL POURS

CONCRETE JOBS OF 1 CUBIC METER OR LESS

• Hand or Small Barrel Mixer on Site

• Residential or Micro Commercial, Post Footings, Small Curbs etc.

Typically used in residential or micro-commercial projects, these small concrete jobs, such as installing small curbs or post footings, are often addressed on-site, where the concrete batches are mixed by hand, with hand tools or small barrel mixers. Volumetric Mixer Trucks are ideal when small pours are technical in nature and engineering requirements call for certification of the finished pour.

Large Pours

WITH READY-MIX TRUCKS

• 6–10 Cubic Meter Capacity

• One Batch Mixed at Plant

• One Pour at a Time

• Foundations, Walls, Floors and Other Structures for Commercial, Infrastructure and Large Residential Projects

When serving the concrete needs of larger commercial, residential or infrastructure projects, such as building houses or apartments, usually ready-mix trucks are employed. The typical trucks have a 6-10 cubic meter capacity and their concrete batches are produced off-site at a concrete plant. These large batches are mixed at the plant and are delivered in big ready-mix drum trucks in one large pour and the trucks need to rotate their drums constantly to prevent over-curing, which can ruin the load. This is why they are often known as “hot loads”, because they have to be used within a certain timeframe.

PROMIX FLEXIBLE POURS

THE PERFECT ON-DEMAND “MIDDLE-ROAD” SOLUTION!

• 6–8 Cubic Meter Capacity

• Minimum 1 Cubic Meter Pour

• Several Smaller Pours or One Large Pour

• Each Pour Mixed at Client Site to Meet Client Specifications and Timing

• Small Foundations, Sidewalks, Landings,

Stairs, Infrastructure, Backfill and

Specialized Pours

Our ProMix trucks have a 6- 8 cubic meter capacity, with the flexibility to deliver several smaller pours (minimum 1 cubic meter pour required), or one larger pour, each with the capability to custom-mix at your job site. This makes our trucks uniquely versatile, allowing us to serve anything from smaller to larger loads, perfect for anything from commercial to residential projects, small foundations, sidewalks, stairs, infrastructure, backfill and other specialized pours. And since our Volumetric Mixer Trucks produce concrete on-site, unlike ready-mix trucks, we can customize each batch to meet your project requirements. Plus, it’s on-demand. We don’t start pouring until you require it.

Timing is Everything

If you’ve ever dealt with concrete, you know that the slightest offset in timing can ruin the whole batch. If it sits too long, it can start to set or harden and chemicals then need to be added to slow the hardening process. That’s why traditional ready-mix trucks have had to mix up big loads at the plant and then rush to the job site to discharge the concrete. If the concrete ‘warms’ and begins to harden by delays on-site, or a few extra kilometers in-transit, it can lead to ruined batches, extra delays, extra costs and added stress when it comes to your project management.

That’s Why, When it Comes to Working With Concrete, Fresh is Best.

Unlike ready-mix trucks, our ProMix Volumetric Mixer Trucks don’t require a trip to the concrete plant because they custom mix fresh concrete on-site, eliminating painful time restraints and “hot loads” that lead to over-cured concrete. New technology allows our Volumetric Mixer Trucks to start mixing at any time. We arrive on-site, get the go-ahead from you and start pouring a fresh load of concrete exactly when you need it, perfectly mixed and perfectly matched to your job requirements.

Recipe For Success

HOW DOES ON-DEMAND CONCRETE WORK?

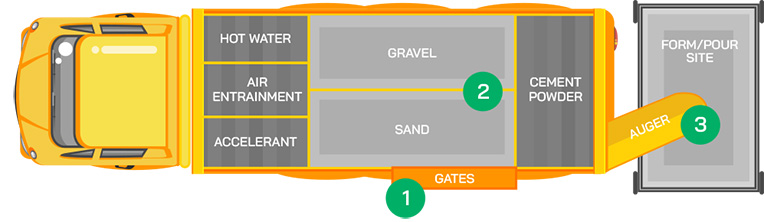

It’s like having a concrete plant right on board the truck! Our ProMix Volumetric Mixer Trucks contain onboard sand, gravel, water, cement powder and several choices for additives. Choose your mix and inside the truck these remarkable steps take place:

STEP ONE

THE DRIVER CONTROLS THE

ADJUSTABLE MATERIALS

After we consult with you on your

concrete specifications, the driver can adjust the material gates to ensure the correct amount of each material is

dispensed into the mixing auger.

STEP TWO

MATERIALS ARE DISPENSED TO

THE AUGER

The specified amounts of sand, gravel, cement powder and additives

(accelerant, air entrainment, hot water) are all dispensed into the auger.

STEP THREE

MATERIALS ARE CUSTOM MIXED AND “FRESH” CONCRETE IS DISPENSED

All materials are mixed while being

transported by the auger into the pour site. The concrete mix is as fresh as

possible and is tailored to the

customers’ needs.

Need the right recipe for construction backfill, residential foundations, or specialized mixes that require accelerants or air entrainment (tiny air bubbles in the concrete)?

Tell us what you need and we’ll put together the right custom mix for you on-site.

No waiting. No delays. No lost productivity. Fresh concrete, right on-demand.

Some of Our Secret Concrete Recipes for Superior Results…

DO YOU WANT CONCRETE THAT IS STRONG?

PERFECT FOR:

Areas with high structural importance such as building walls, floors and foundations. Also, when a surface is expected to take a lot of impact, like an industrial shop floor.

THE PROMIX SOLUTION

ProMix concrete is made to be durable and dependable. The more cement powder that is added to the mix, the more weight and impact the finished concrete can withstand.

DO YOU WANT CONCRETE THAT IS RESILIENT?

PERFECT FOR:

Concrete structures that are exposed to cold weather like exterior walls, bridge superstructures and roadways.

THE PROMIX SOLUTION

For robust, hardy concrete, air entrainment is added to the mix to create tiny bubbles throughout the finished concrete, so that it can expand and contract without breaking.

DO YOU WANT CONCRETE THAT IS FAST-SETTING?

PERFECT FOR:

High traffic areas such as busy highways or when a project needs concrete to set before the next phase can go ahead.

THE PROMIX SOLUTION

For projects that need fast-setting concrete, an accelerant can be added to the mix in measured amounts. This will ensure that the concrete sets faster and can make all the difference to project deadlines.

DO YOU WANT CONCRETE THAT IS PROTECTIVE?

PERFECT FOR:

Pipe conduits and as structural fill in construction applications.

THE PROMIX SOLUTION

With the right proportions of cement, sand, gravel and additives you can produce controlled density fill concrete (CDF). CDF is uniquely useful as a free-flowing, compacted and dense, non-settling backfill.